TAILOR MADE FRAMES

HOW DO I ORDER A TAILOR MADE FRAME?

WHAT MASS CAN I INFLUENCE ON A TAILOR MADE FRAME?

WHAT IS THE DIFFERENCE BETWEEN A CUSTOM FRAME OPTION AND A TAILOR FRAME?

HOW MUCH DOES A TAILOR MADE FRAME COST?

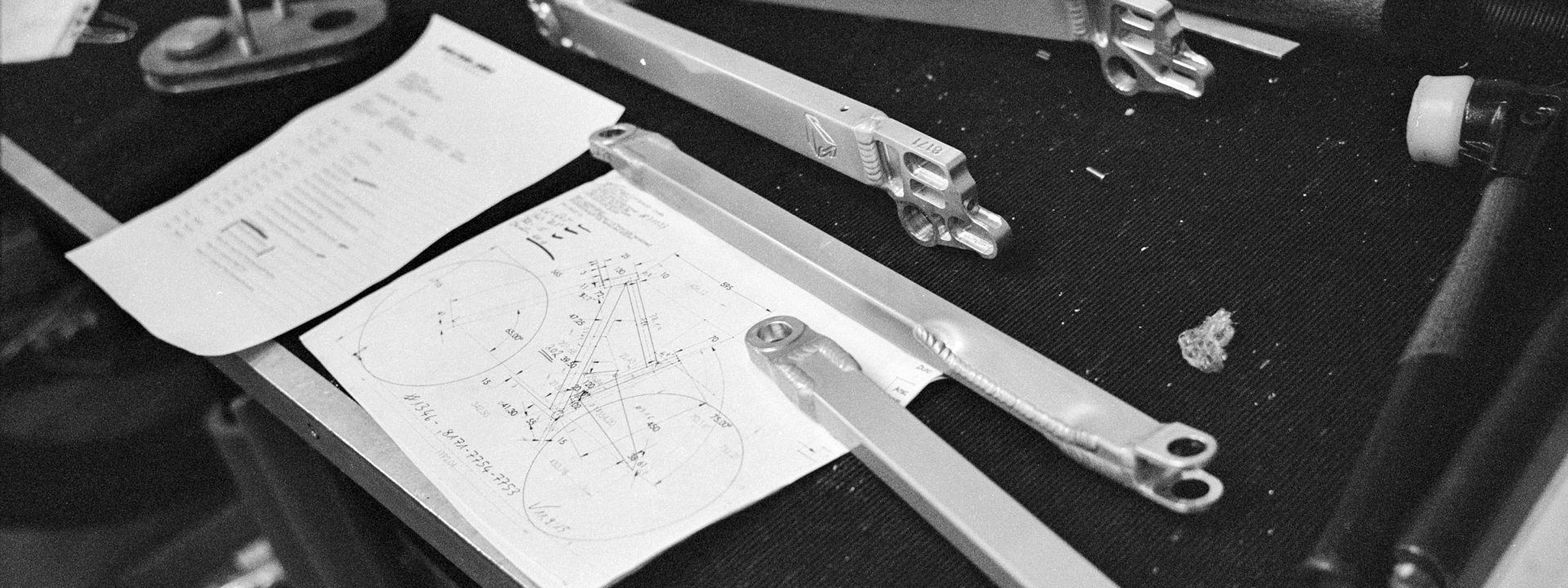

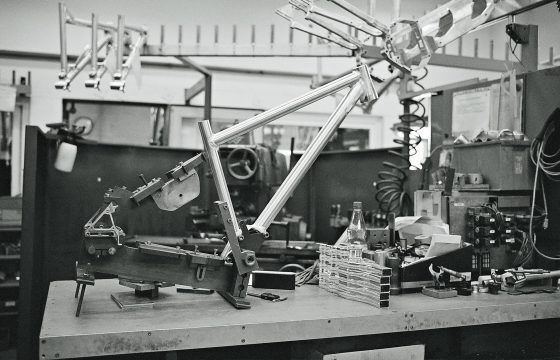

AN EXAMPLE FROM OUR TAILOR MADE FRAME PRODUCTION

THE NICOLAI ARGON FAT TANDEM

A TAILOR MCADE STORY

ION 16 XXS, 26“. CUSTOMER: 153cm, 45kg Advice and delivery: Radsport Kimmerle, Gärtringen

Looking at the variety of MTBs and even gender-specific frame designs on the market, one might think that the anthropometrically recorded range between the 5th and 95th percentile can be served with the range of frame sizes. With Isabella from the northern Black Forest, however, the search for the right bike is not so easy. With 153cm and 45kg it is dainty, but is located above the…

YOU WANT A NICOLAI TAILOR MADE FRAME?

JUST WRITE US A MESSAGE. WE WILL CONTACT YOU AS SOON AS POSSIBLE.

100% HANDMADE

All NICOLAI frames are

manufactured in Germany. This is

the only way to ensure our high

quality standards in the long term.

TESTRIDE

Test rides can be done anywhere

in Germany. Try it!

HOMESERVICE

Unique. Any damage will be

repaired at your home. No more

visits to the workshop.

WARRANTY

From the date of purchase you get

5 years warranty. We also ensure

a ten-year supply of spare parts.